Local

manufacturer

prospers with expanded Port site, builds number of family-wage jobs

When the

Port of Walla Walla added a new 7,680 square foot building to Reiff Manufacturing’s airport complex

it set the stage for new efficiency and continued growth

for the fiberglass fabricator.

David Reiff, President and General Manager

of the firm, explains that the $540,000 Port investment

allowed consolidation of all manufacturing processes

to a single site instead of operating from two locations

a “block and a half ” apart.

According to Reiff, having its multiple

building complex in one location added needed efficiencies in the manufacture

of a variety of custom-built products. The mix includes

fiberglass shelters, antenna covers, cisterns and fish

rearing troughs and tanks.

Even though annual sales to worldwide

markets have grown to an estimated $3 million, Reiff

insists his is a “small business.”

Reiff Fiberglass operates with a staff

of 20 people. The total annual payroll is some $700,000.

David Reiff says his family-owned business

is staffed by familyoriented people. “I’d

say most all of our employees are here to earn a salary

that meets a Walla Walla family’s needs.”

It’s not just the individuals who work for the manufacturer who benefit. Reiff is particularly committed to other local

businesses to help make his a success.

“We rely on as many as 100 vendors

on a regular basis - suppliers, electricians, welders

- craftsmen who help us build quality products that

are competitive on an international scale,” Reiff

explains. “And as many as 50 or more of those

are Walla Walla based. It’s just important that

we help each other grow together.”

Reiff Manufacturing was started in 1963

by David’s grandfather, Norwood. Later, his father

Steve Reiff took over the reins. David and his wife,

Michelle, assumed ownership and management of the company

in March, 2011.

|

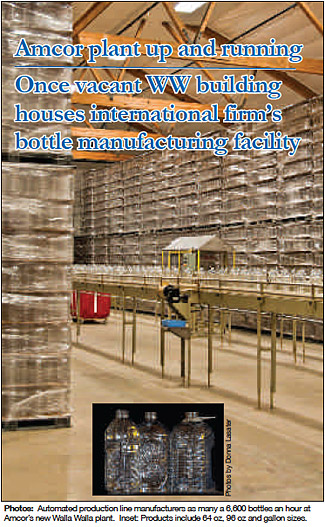

A once vacant warehouse

in the Port’s Dell Avenue Industrial Park is now home to a state-of-the-art bottle maker

operated by an international packaging company.

Since February, 2011 the Amcor plant

has been manufacturing PET (polyethylene terephthalate)

bottles for juices produced by Cott in the next-door

plant formerly owned by Cliffstar.

According to Jeremy Larson, site manager

for Amcor, the highly automated plant produces as

many as 6,600 bottles an hour in 64-ounce, 96-ounce

and gallon-sizes.

From start to finish, bottles are

seldom, if ever touched by human hands. The sophisticated

system is operated by a two-person crew per shift,

with each keeping a close eye on equipment that’s

finetuned to maintain high speed output with uncompromising

quality. Once wrapped and stacked, the bottles are

stored by the thousands awaiting use by Cott.

Larson says the Walla Walla plant

is one of 78 similar Amcor operations in 13 countries around the world. “We’re

counting on growing our service base beyond Cott’s Walla

Walla plant to other users in nearby Northwest sites,”

Larson said.

Improvements costing an estimated

$100,000 were completed to ready the building for

Amcor. The renovations were funded through an Economic

Development Sales Tax Grant via an agreement between

the Port, Walla Walla County and the City of Walla

Walla.

|